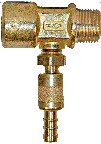

Downstream injectors are installed after the pump. In order to function, the pressure must be lowered with the use of either a dual lance and soap nozzle, a variable nozzle, a dual nozzle holder, or an adjustable nozzle holder. Water enters the inlet of the injector and creates a venturi which drops the pressure and suctions the chemical from container. Chemical can be injected either in concentrated form or in diluted form. The injection rate for this injector is set at the factory and not adjustable. The injector contains a check valve to prevent water from flowing into the chemical container while in high pressure mode.

NOTE: Length of hose will determine ability of injector to work properly. It is recommended to keep hose length at 100 feet or less

SPECIFICATIONS:

- Maximum pressure: 3600 PSI

- Maximum temperature: 300F.

- 2.3 to 6.5 GPM flow rate

Reviews

There are no reviews yet.